When assessing the structural integrity of pipes, tanks, and pressure vessels, one of the most reliable methods used across industries is hydrostatic pressure testing. This tried-and-tested technique plays a vital role in preventing catastrophic failures, protecting personnel, and preserving the integrity of critical infrastructure. At Armfield, we not only understand the science behind hydrostatic pressure testing—we provide innovative, accurate, and education-focused solutions that support industries, research facilities, and academic institutions worldwide.

From detecting hidden flaws to ensuring regulatory compliance, hydrostatic pressure testing is more than just a safety check—it’s a pillar of responsible engineering. Let’s dive into what makes this method so essential and how Armfield’s hydrostatic pressure testing solutions support excellence across sectors.

What is Hydrostatic Pressure Testing?

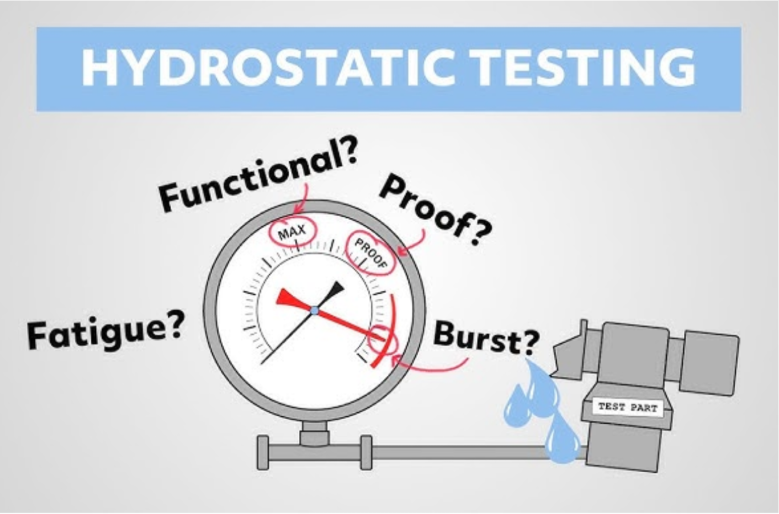

In simple terms, hydrostatic pressure testing is a non-destructive testing method that involves filling a vessel, pipe, or tank with water (or another incompressible fluid) and pressurising it to a designated level to check for leaks, deformations, or failures. This pressure is typically held for a set duration, during which any loss of pressure or visible leakage may indicate a fault in the structure.

The process is widely used because it mimics the real-world pressure conditions that the equipment will endure during operation—without introducing the risks of gas-based testing. When assessing the structural integrity of pipes, tanks, and pressure vessels, one of the most reliable methods used across industries is hydrostatic pressure testing.

Why is Hydrostatic Pressure Testing So Important?

Industries such as:

- Oil and Gas

- Chemical Processing

- Power Generation

- Water Utilities

- Aerospace and Defence

…all rely heavily on pressurised systems that operate under significant stress. Even a minor flaw in one of these systems can lead to environmental disasters, operational downtime, or serious injury.

This is why hydrostatic pressure testing is not just a technical requirement—it’s an industry standard for ensuring safety, efficiency, and regulatory compliance. It provides clear data on structural resilience, confirming that materials and welds are free from defects and fit for service.

How Armfield Supports Hydrostatic Pressure Testing

At Armfield, we offer comprehensive hydrostatic testing solutions tailored to meet educational, industrial, and research needs. Our products are trusted by engineering faculties, research institutions, and industry specialists alike.

Whether you’re teaching students the fundamental concepts of fluid mechanics or conducting full-scale hydrostatic assessments in the field, Armfield’s modular and high-precision systems deliver both performance and reliability.

Our hydrostatic pressure testing rigs are:

- Accurate – built with precision gauges and pressure control mechanisms

- Safe – designed with safety valves and secure housing to prevent accidental overpressurisation

- Flexible – configurable for various pressure levels, pipe diameters, and test durations

- Durable – made with corrosion-resistant materials for long-term use

- Instructional – backed by comprehensive manuals and teaching aids for practical learning

So when assessing the structural integrity of pipes, tanks, and pressure vessels, you can count on Armfield to deliver effective, hands-on systems that replicate real-world testing conditions.

Education Meets Industry: Teaching the Next Generation

While hydrostatic pressure testing is a staple in industry, it is equally vital in engineering education. Students need to understand why it works, how it works, and what its limitations are. That’s where Armfield’s hydrostatic teaching units come into play.

Our educational apparatuses allow students to:

- Conduct real-time hydrostatic tests

- Visualise the effects of pressurisation

- Explore failure modes and safety thresholds

- Understand the physical laws governing fluid pressure

By bringing theory into practice, we empower students with the confidence and competence to carry these critical skills into their future careers.

Supporting Long-Term Asset Reliability

When assessing the structural integrity of pipes, tanks, and pressure vessels, regular hydrostatic testing doesn’t just prevent failures—it helps extend the life of equipment. Detecting small leaks early allows for timely repairs, reducing the risk of large-scale outages or costly replacements.

Hydrostatic pressure testing also supports predictive maintenance strategies, enabling facilities to plan interventions before issues escalate. For asset managers and engineers, this translates into cost savings, improved performance, and peace of mind.

And with Armfield’s user-friendly, scalable systems, even complex hydrostatic pressure testing protocols can be executed with confidence.

Complying with Standards and Regulations

In many industries, hydrostatic pressure testing is not optional—it’s a legal and regulatory requirement. Standards set by agencies like:

- The American Society of Mechanical Engineers (ASME)

- The European Pressure Equipment Directive (PED)

- And the British Standards Institution (BSI)

…all call for strict compliance in how pressure vessels are tested and certified.

Armfield systems are designed to help organisations meet these standards by offering repeatable, accurate testing environments. Our commitment to quality, traceability, and support makes us a trusted partner in maintaining compliance and operational excellence.

Why Choose Armfield?

As a company with over 50 years of experience in engineering education and applied research, Armfield brings unmatched expertise to the table. We understand the critical role hydrostatic pressure testing plays in both industry and academia—and we engineer our systems accordingly.

Here’s why clients trust us:

- Proven heritage: decades of service to global universities and technical institutions

- Unmatched support: from product training to technical consultation

- Customised solutions: we can tailor rigs to your unique application

- Continuous innovation: we evolve with industry needs and educational trends

Whether you’re testing new composite pipelines or instructing undergraduates on failure modes, Armfield has a hydrostatic pressure testing solution built for your needs.

Ready to Enhance Your Hydrostatic Testing Capabilities?

If you’ve been wondering how to improve your current testing methods, or you’re building a new lab environment from scratch, Armfield is here to help.

When assessing the structural integrity of pipes, tanks, and pressure vessels, one of the most reliable methods used across industries is hydrostatic pressure testing—and with Armfield’s trusted solutions, you’re in the safest hands.

👉 Contact us today to discuss your requirements and discover how we can support your hydrostatic testing needs.